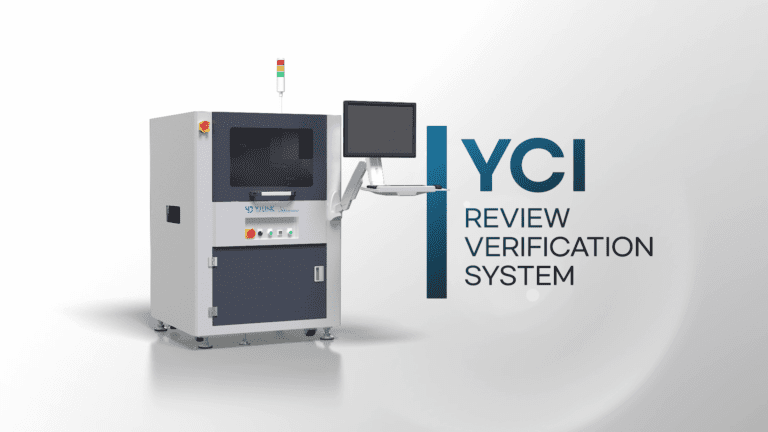

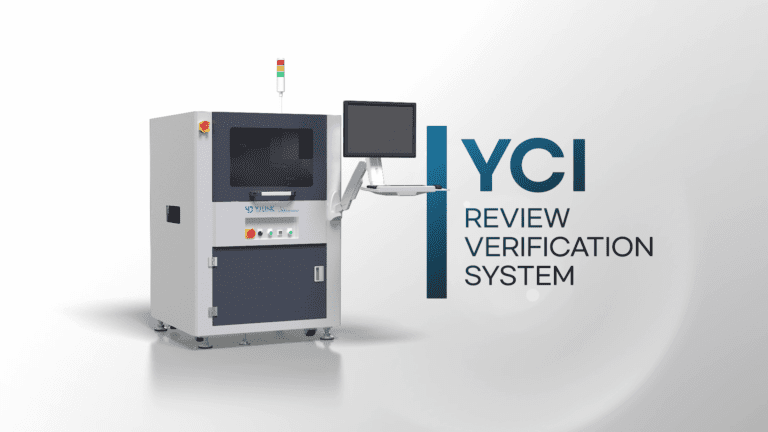

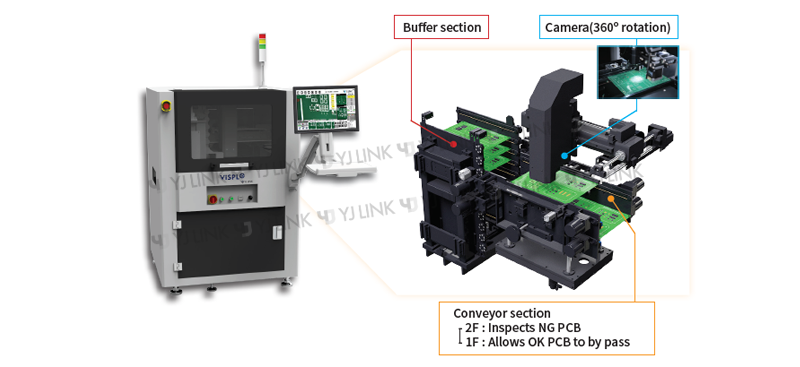

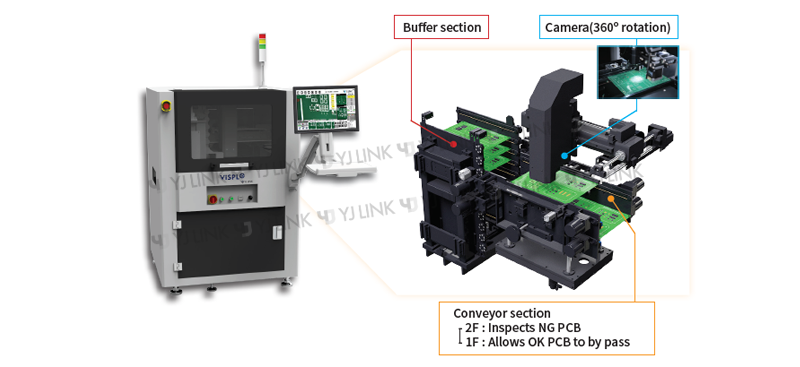

VISPLO Review Verification System

Located downstream of the AOI, that receives NG information of PCB and inspect with a 360 degree camera, allowing the operator to determine whether it is NG/OK and accurately detect false defects.

Play Video

Description

This machine located downstream of AOI that receives NG information from AOI, with a camera moving to the respective location on the PCB, and sends the actual image to the screen, allowing the operator to determine whether it is NG/OK and accurately detect false defects.

Features

- Buffer section : NG PCB stacking

- Conveyor section of 2-layer structure(separate operation)

- Conveyor 2F : Real image inspection through 360˚ camera rotation

- Conveyor 1F : Good PCB by pass

- PCB 10 slots (60mm/pitch)

- Safety Cover

- ARINET+ARS program

| No. | Items | M | XL |

|---|---|---|---|

| 1 | PCB Min.Size(L)x(W)mm | 70 X 70 | |

| 2 | PCB Max.Size(L)x(W)mm | 330 X 250 | 460 X 460 |

| 3 | PCB Thickness(mm) | 0.3 ~ 4.0 | |

| 4 | PCB Edge(mm) | 3 | |

| 5 | PCB Top/Bottom Clearance(mm) | 30 / 30 | |

| 6 | PCB Loading Weight(kg) | 1 | |

| 7 | Conveyor Speed(mm/sec) | 200 | |

| 8 | Conveyor Belt | Timing Belt | |

| 9 | Transport Height(mm) | 950±20 / 900±20 | |

| 10 | Flow Direction | Left to Right / Right to Left | |

| 11 | Fixed Rail | Front / Rear | |

| 12 | Buffer Section | 10 slot (60mm/pitch) | |

| 13 | Camera Location Accurach(mm) | -0.05~0.05 | |

| 14 | Camera X/Y-axis Speed(mm/sec) | Max 500 | |

| 15 | Ingerface | SMEMA | |

| 16 | Air Supply (Mpa) | 0.5(5bar) | |

| 17 | Air Useage (ℓ/min) | 60 | |

| 18 | Electricity Comsumption(kw) | 2 | |

| 19 | Dimension(L)x(W)X(H)(H-1)mm | 1100 X 1060 X 1600(2060) | 1340 X 1250 X 1650(2110) |

| 20 | Weight(kg) | 700 | 800 |

| 21 | Camera Module | Specification:5m pixel / Resolution:2.2um / Zoom:80~120 fix / Rotation:360 degree full | |

| 22 | Power | 220~320V/50~60Hz, 1Phase | |

| 23 | Color | SR RAL 7035 + UT-730M R/T Doosan MT Dark gray(G-40) | |