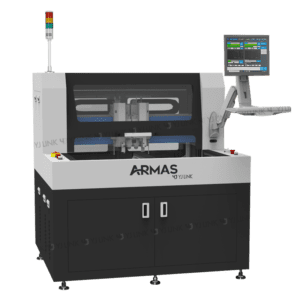

Products

Check out for YJ Link's SMT

Browse the list of YJ Link's technology and products for SMT automation process.

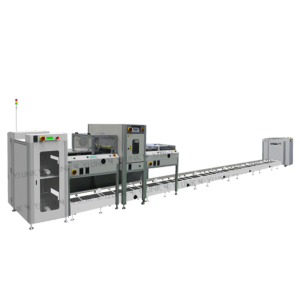

SMT in line system lay-out

Customize your SMT line with YJ Link's products.

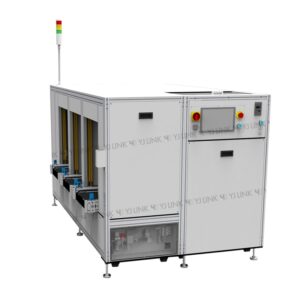

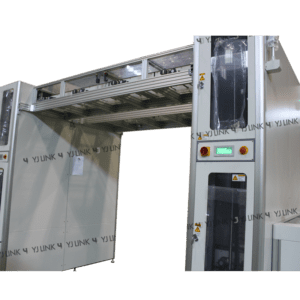

Smart Conveyor System

The MICOM system enables Smart Conveyor System and Smart SMT Line.

Browse the catalogue of our PC-controlled SMT Line devices.

Browse YJ Link's line of CE board handling equipment.

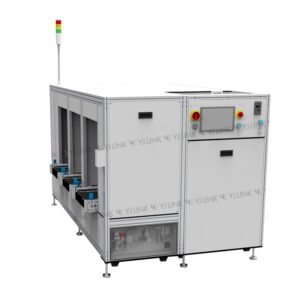

YJ Link's line of non-CE board handling equipment consists of Loader/Unloaders, Buffers, Link/Work and the Conveyor series.

Follows a drawn magnetic line to carry magazine racks in an SMT line.

Accessories for an optimized SMT line.

SMT(Surface-mount technology)

Surface-mount technology(SMT) is a method in which the electrical components are mounted and soldered directly onto the surface of a printed circuit board(PCB).

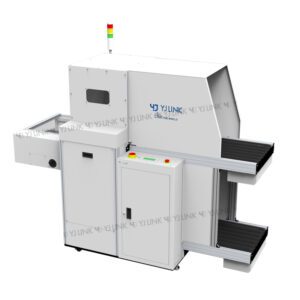

Procedure of surface-mount technology(SMT)

- Loading: Putting in PCBs into the procedure.

- Applying Solder Paste: To mount the components, solder paste is applied onto the surface of a PCB.

- Solder Paste Inspection: Checking whether the paste is applied correctly.

- Mounting: Mounting the components onto the surface of a PCB.

- Soldering: Soldering the said mounted components on a PCB.

- Soldering Inspection: Checking whether soldering is done correctly.

- Manual Inspection: A personnel inspects the PCB manually.

- Unloading: Unloading the finished products from the procedure.