Smart Conveyor System

SMART CONVEYOR SYSTEM

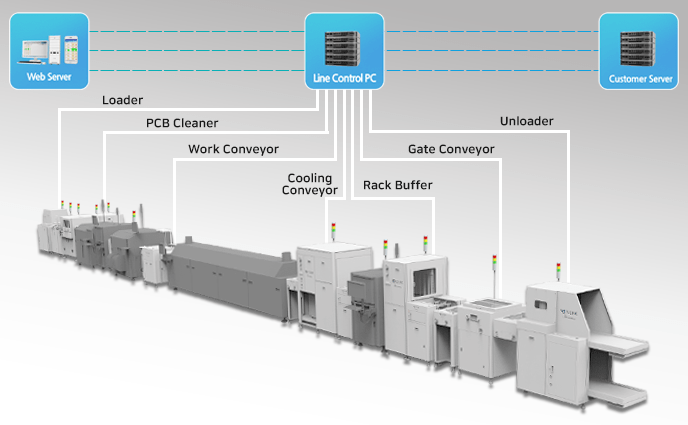

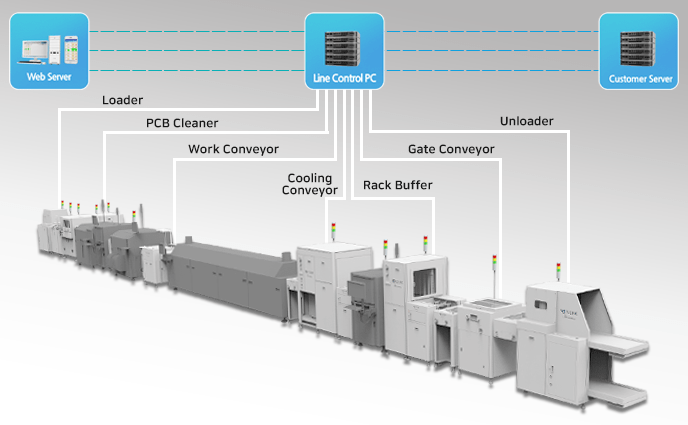

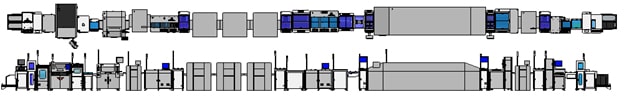

YJ’s Smart Conveyor Systme can build Smart SMT Line. This is a solution that enables an enterprise-wide integrated management and automated production line.

The YJ equipment constituting the smart SMT line is connected to the line control PC(A separate computer for central control of the YJ facilities) through LAN communication. The customer transfers the PCB information to each YJ facility through the line control PC, so that the operator can change the width easily. In addition, it is attracting attention as a next-generation SMT solution that improves the productivity and competitiveness of customers by enabling real-time monitoring of facility status.

*Laser markers communicate separately through client’s server.

Swipe to see more

STANDARD SPEC

| 1) Automatic width adjustment | When applying the data of the production model, each transport device of YJ carries out automatic width control. |

| 2) Real-time status monitoring | Real-time monitoring possible with PC, Laptop, Mobile Device access through URL *Web server only provides monitoring function. |

| 3) Maintenance Alarm Function | If the maintenance period is set to a certain cycle for each equipment, an alarm will ring. |

| 4) ‘LogFile’ Creation | Production history management and infinite data processing |

| 5) Set access permisiions | The user can edit accessibility to the system |

OPTIONS

- Interface between the Line Control PC and Customer’s server

– The Customer SERVER reads the result value of each transport device of YJ’s stored in Line Control PC. - In case of NG Buffer or Unloader, it is possible to trace the board of a specific slot during production

– Serial # required, the factory’s main server has to be connected - Conveyor speed can be set by model

– The machine must be equipped with an electronic speed control controller in advance.

Ex) Cooling Link in front of/ at rear of reflow oven

APLLICATION EXAMPLES

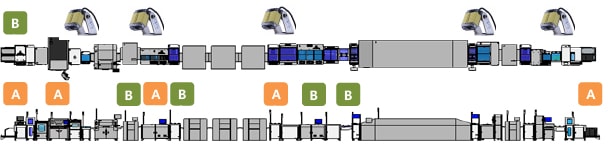

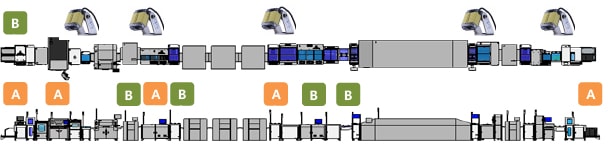

A. All equipment of YJ’s simultaneous width adjustment _ Applied in ‘C’ company

Swipe to see more

- Automatic width control type for next B model production after completion of the work on the model A (After ejecting the magazine rack from the unloader)

B. YJ equipment sequential width control by production model (Cascade) _ Applied in ‘M’ Company

Swipe to see more

-

When new B model is inserted during A model production, automatic width control is performed sequentially each time new B model enters

-

This is the general recommendation since the model change time is shortened

C. Installation of scanning conveyor for product tracking in case of A and B _ Applied in ‘F’ Company

Swipe to see more

-

It is possible to produce more than two kinds of model by auto width adjustment by scanning those models.

-

It is necessary to mount the scanning conveyor at the location where you want to trace the models. The more the number of scanning conveyors, the more accurate the position tracking is possible.

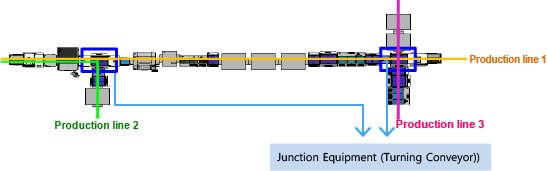

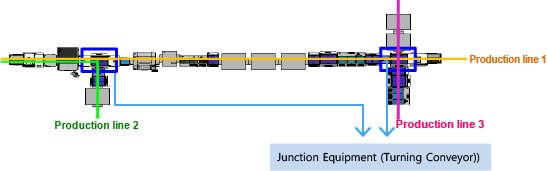

D. Simultaneous production of complex lines _ Applied in ‘F’ Company

Swipe to see more

-

Simultaneous production of multiple products due to production line branching in multiple lines.

-

Simultaneous/Sequential width adjustment